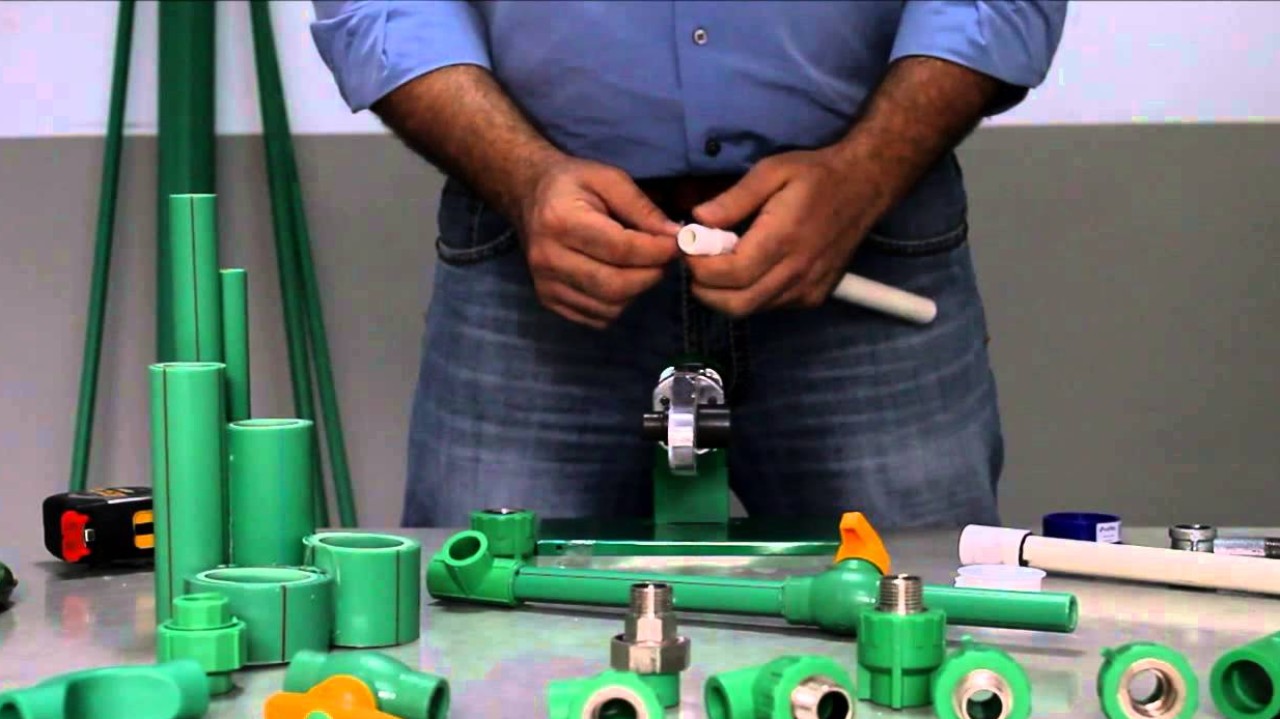

PP-R Hot Melt

Thermofusion is a simple and fast welding method to join random polyethylene pipes and their accessories. The surface of the parts to be joined is heated to melting temperature and they are joined by applying pressure, with mechanical or hydraulic action, according to the size of the pipe and without using additional joining elements.

Suitable for joining pipes with the same ø/thickness ratio, with diameters from 20 mm to 630 mm.

This technique produces a permanent and effective bond, and is inexpensive.

To achieve a correct thermofusion welding, the following factors must be considered:

- Heat of fusion

- Proper Fusion Pressure

- Melting speed

- Cooling pressure

- Correct thermo element temperature

- Suitable environment temperature

- Using proper heating and cooling times

- Correct alignment

- Avoid contact with dirt, oils and residues

MAIN FEATURES OF THE PP-R THERMOFUSION SYSTEM

- Absence of Corrosion: The Thermofusion system (PP-R) resists any type of water hardness and supports chemical substances with a PH value between 1 and 14.

- Absence of scaling and lower pressure drop: The tube has a lower pressure drop due to the internal walls of the tube, which are perfectly smooth, and also prevent the formation of scale.

- Wear resistance: Allows high water speeds to be obtained without erosion problems.

- Duration in time: More than 50 years, depending on temperature and pressure.

- Less noisy and faster installations: The elasticity and sound absorption prevent the propagation of noise and vibrations caused by water. In addition, the low weight of the material allows installations to be carried out between 30% and 50% less time, compared to traditional products.

- Suitable in seismic hazard zones: Plastic materials are not rigid inside structures, therefore, they are suitable for seismic zones.

- Thermal dispersion and limited condensation: Thermofusion PP-R, like all plastic materials, is a poor conductor of heat, therefore, an excellent thermal insulator.

- Resistance to ice: Given the typical elasticity of the Thermofusion (PP-R) system, the section of the tube increases, assuming the volume of the frozen liquid inside it.

- Absolute non-toxicity: The system used for the production of the materials is completely non-toxic and meets the hygienic-sanitary standards.